Developing incremental improvements to current ceramic laser printing equipment and testing their commercial viability, as well as identifying the technical specifications for the next generation of ceramic digital printers.

At a glance

- ILPEC responded to the findings of the AHRC funded project: Extending the Potential for the Digitally Printed Ceramic Surface.

- The team developed immediate design improvements to the equipment and demonstrated their commercial value through tests conducted under commercial conditions.

- The longer-term development of the technology was also supported through the creation of a specification for the next generation of dedicated digital ceramic printing machines.

Key details

Gallery

More information

The challenge

The research undertaken for ‘Extending the Potential for the Digitally Printed Ceramic Surface’ demonstrated that the new digital ceramic print technology was capable of delivering high-quality and commercially viable results. However, the work uncovered technical limitations to the equipment with respect to consistency in high-volume or multiple pass print runs. The team needed to develop short-term solutions to enhance the current machines’ capabilities and support future advancements in the technology by initiating a productive dialogue between users and manufacturers.

Partners

To ensure the commercial print runs were undertaken in a commercial environment and to a commercial brief, the research team partnered with the design studio Santorus to produce a limited run of their digitally created ceramic surface designs.

Our approach

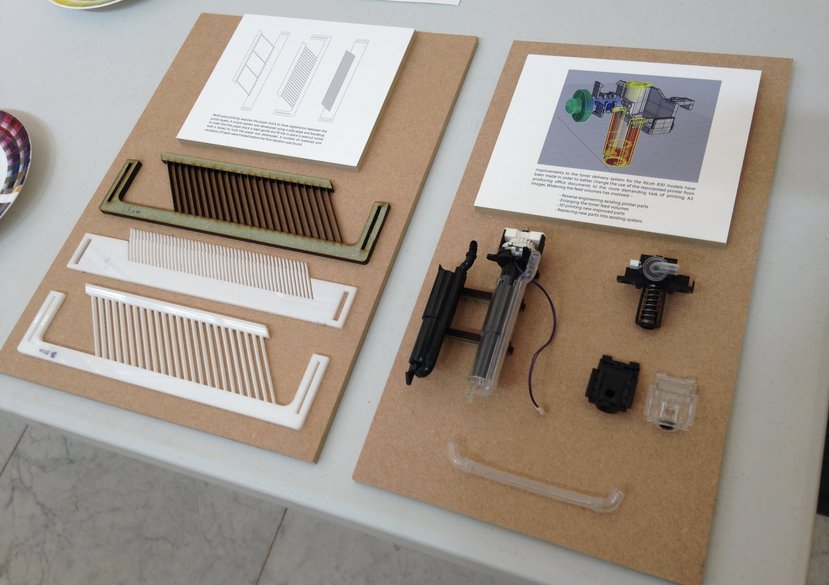

The project team focused on resolving the two key technical barriers to wider use of the technology for high volume, multi-colour accurate ceramic transfer printing. The first was the inability of the current toner delivery system to handle the large quantities of different coloured mineral pigments necessary for large runs of ceramic transfers. The second was the poor registration accuracy of the printer's paper feed mechanism. These were both addressed through iteratively designing prototype elements. In the case of pigment delivery, this meant replacing current parts with 3D printed ones. To improve the accuracy of the paper feed an entirely new feed registration mechanism was constructed. The new paper feed system and pigment delivery parts were tested by prototyping multi-pass print designs requiring high-tolerance registration and by printing batch production runs under commercial conditions.

Alongside this, the research team held discussions with potential and current stakeholders in the new technology, through one-to-one sessions and group meetings. This was to understand individual perspectives regarding the possible extended needs of users, the pressures on, and aspirations of, the suppliers of the equipment and pigments, and the position of intermediaries, such as designers and colour specialists.

Outputs

CAD files

CAD working drawings for a unique registration system enabling multi-pass printing for A3 Ricoh 830 and 840 model laser printers.

Working CAD files that allow the fabrication of 3D printed parts to replace and improve the quantity of toner flow for a Ricoh Aficio SP C830DN laser printer.

Prototypes and production runs

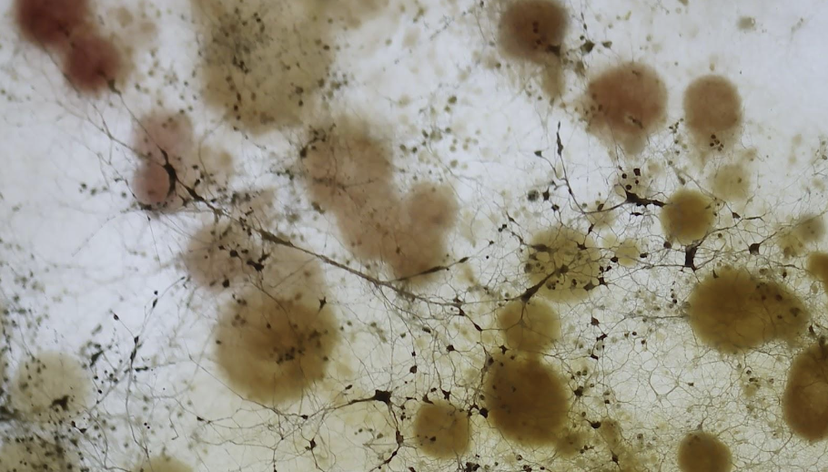

Brown, S. (2018) Prototypes demonstrating visual qualities realised through technical developments in the printing equipment.

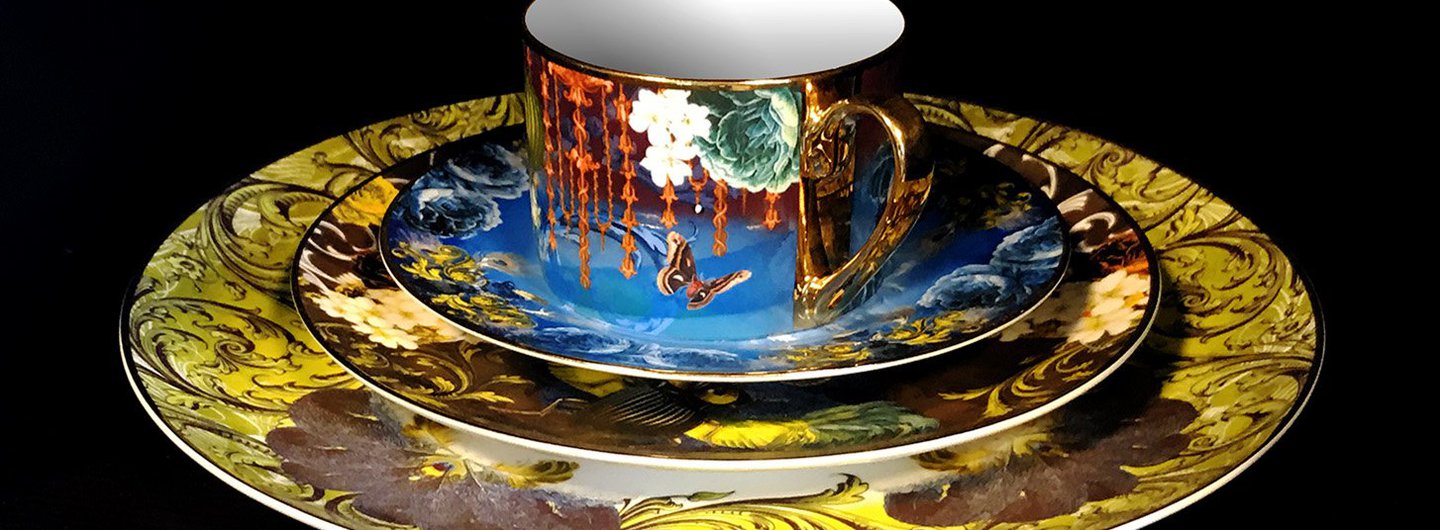

Smith, M. (2018) Digitally Printed Tableware Designs

Brown, S. and Smith, M. (2018) Production run of digitally printed bone china for commercial partner Santorus Ltd.

Publications

Oakley, P. (2018) Creating a Brighter Future? Responses to the commercialisation of a new ceramic print technology Making Futures, vol.5.

Presentations

Oakley, P. (2017) ‘Protecting Productive Crafting: identifying and supporting crafting in industry in the 21st Century’. Presentation at the Crafting in Industry workshop at Making Futures 5 conference, Plymouth 21 –22 September 2017.

Parkinson, N. and Oakley, P. (2019) A public presentation of selected holdings from the RCA Colour Reference Library and related ceramic objects, including prototypes created for the ILPEC project. Delivered as part of Chemfest 2019, 10 April 2019

Oakley, P. (2019) ‘Combining Materials and Concepts: the case of ceramics in Western art’. Seminar delivered to Shanghai Centre of Public Art faculty, Shanghai University, 22 May 2019.

Oakley, P. (2019) ‘Digital Printing for Ceramics’. Seminar delivered to the Industrial Craft programme at Thammasat University’s Lampang Campus in Northern Thailand, 4 Dec 2019.

Exhibitions

ILPEC work in progress pop-up exhibition at Making Futures 5, 2017.

A selection of the print prototypes were displayed at Spring Fair 2017 at the National Exhibition Centre, Birmingham, UK.

The material project outputs were displayed at the British Ceramic Biennial, Stoke on Trent, 23 Sept-5 Nov 2017.

Smith, M. (2017) Spaces and Places exhibition, Marsden-Woo Gallery.

A selection of the print prototypes were displayed at Top Drawer, Olympia, London, 14-16 Jan 2018.

A selection of the print prototypes were displayed on a commercial manufacturers trade stand at Ambiente Trade Fair, Frankfurt, Germany, 9-13 Feb 2018.

Lead

Professor Martin Smith

Principal Investigator

Team

Ask a question

Get in touch to find out about School of Arts & Humanities research projects.

SoAH@rca.ac.uk