Designing and testing a small-scale retort for making charcoal that uses the flammable gases generated by the charcoaling process to reduce the carbon footprint.

At a glance

- Developing a Small Sustainable Charcoaling Retort is led by Professor Peter Oakley in partnership with the Flax Project CIC.

- The project began with a review of existing charcoal clamps and retorts and their key advantages and issues from practicality, sourcing, and sustainability standpoints.

- The new design uses the complex hydrocarbon gases that are generated by the charcoaling process to help heat the retort, reducing air pollution and the overall amount of wood needed for the firing.

- The retort has been designed so it can be assembled from readily available, pre-existing standard parts and constructed using manual power tools.

- The project involves the construction of an iterative series of working retorts, which are being fired at the Flax Project’s farming site in Cornwall.

- Developing a Small Sustainable Charcoaling Retort is a sister project to the Charcoal Fire Assaying project, also led by Professor Oakley.

Key details

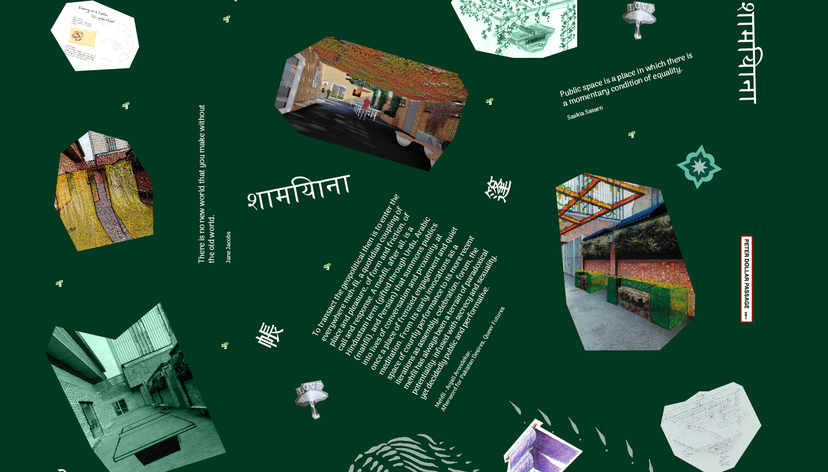

Gallery

More information

Partners

Flax Project CIC

Flax Project CIC was incorporated in April 2023. It grew out of the Flax Project, founded by Vicky Putler in 2020. The Flax Project’s vision is a sustainable, green, UK textiles/fibre industry – from field to fabric. The CIC has a mission to be the flax processing hub for the Southwest of the UK, creating a local linen. Through practical experimentation, public workshops, and community flax growing activities, the Flax Project CIC is building a community around local textile production.

The challenge

Charcoal is very versatile, being widely used as a fuel source, as a non-polluting and reliable soil improver, and even as an artist’s drawing material. If making and using charcoal as a fuel is treated as part of a responsible, regenerative cycle, it is much less environmentally harmful than burning fossil fuels. Making charcoal using wood from sustainably managed woodlands or from end-of-life wood products brings a wide range of environmental advantages.

However, the traditional process for making charcoal involves the production of significant amounts of pollutants: as well as emitting CO2, a charcoal clamp releases wood gas (a variable mixture of complex hydrocarbons) into the atmosphere.

A more sustainable solution is a charcoal retort. This uses the generated wood gas in the firing process, resulting in cleaner emissions as well as requiring less wood for the firing, reducing the overall carbon footprint in comparison to a clamp.

Key barriers to the wider adoption of retorts are the complexity of most existing retort designs and the specialist construction methods they entail. Whilst simpler designs of retorts are available, these typically use a 45 Gallon drum as the retort vessel, which makes loading, unloading, and handling difficult.

Our approach

The new retort design responded to five key parameters:

- The design needed to turn a high percentage of the wood in the retort chamber into high quality charcoal (ideally 95-100%).

- The design had to use the complex hydrocarbon gases that are generated by the charcoaling process to help heat the retort, thus reducing air pollution and the amount of wood needed for the firing.

- The retort had to be designed so it could be assembled from readily available, pre-existing standard parts and constructed by one person, using only standard manual power tools.

- The retort had to be small enough to be easily loaded, unloaded, lifted, and carried a short distance by one average-strength adult.

- The retort had to be safe to use, with the fire hazard reduced as far as possible.

Activities

The project involves the construction of an iterative series of working retorts, which are being tested at the Flax Project CIC’s farm site in Cornwall.

Once the final design has been developed and confirmed as the best option, a series of test firings determining the retort’s carbon footprint will be undertaken and the results published, along with the plans for constructing the retort. The report will include measurements of the amount of wood charcoaled and consumed in each firing. The report will also identify the Scope 3 aspects related to the process, and give figures when these are calculable and relevant.

Developing a Small Sustainable Charcoaling Retort is a sister project to the Charcoal Fire Assaying project, also being led by Professor Oakley. In combination the results will enable a practitioner to produce charcoal on a small scale and then use this material to fire a muffle furnace following the design developed for the Charcoal Fire Assaying project (which can then be used for cupellation, granulation, or casting). The carbon accounting measurements calculated as part of both projects will allow the carbon footprint of this entire chain of operations to be determined.

Outputs

Demonstrations

The new retort design will be demonstrated at the Flax Project’s summer open day in July 2025.